Home Ceramic PTC Tower Fan Heaters are generally equipped with energy-saving features, which is one of the reasons why they are so popular on the market. Here are some of the energy-saving features of...

READ MORECATEGORIES

Ice Crusher Manufacturer

-

SBJ-A1

SBJ-A1

Fully Automatic Stainless Steel Ice Crusher

-

SBJ-B1

SBJ-B1

Household Simple White Ice Crusher

-

SBJ-C1

SBJ-C1

Extremely Fast Cooling Stainless Steel Ice Crusher

Look no further than our high-quality ice crushers. With their sleek design and powerful blades, our ice crushers will effortlessly crush ice cubes into fine, fluffy snow-like textures in seconds.

- 50Hz, 55W

- 600ml

- Stainless Steel Fittings

- Crushes 300g Ice Per Minute

About Us

Ningbo Shuaige Electric Appliance Co., Ltd.

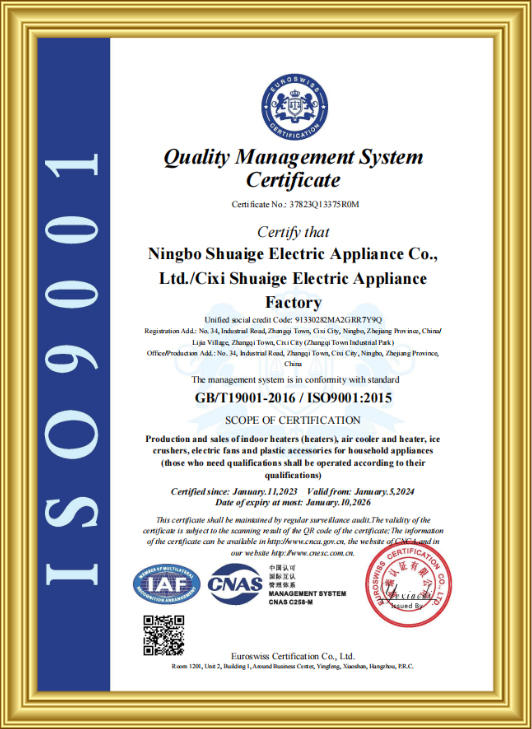

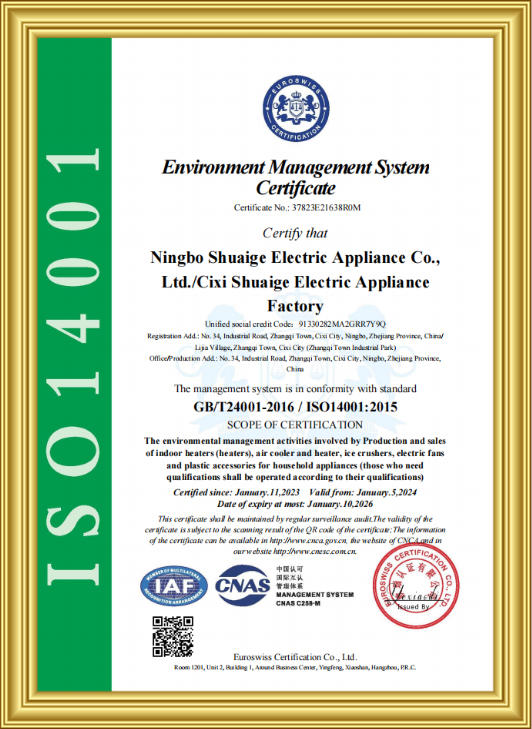

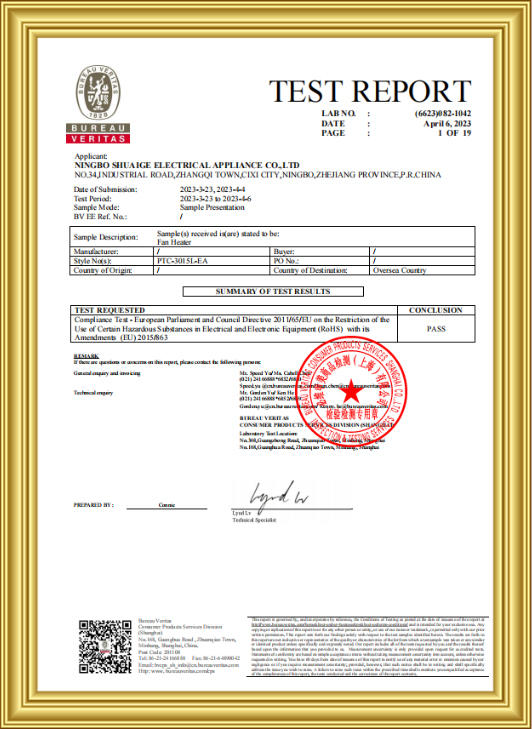

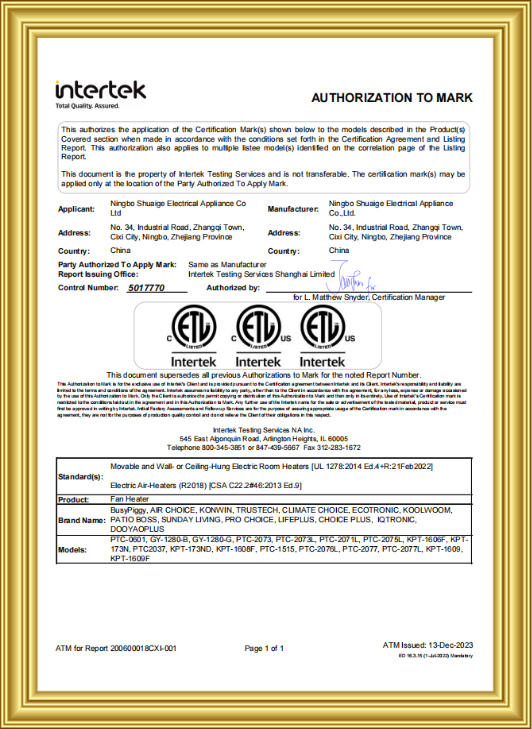

Ningbo Shuaige Electric Appliance Co., Ltd. is a China Ice Crusher Manufacturer and OEM/ODM Ice Crusher Company, covers an area of 20000m2. with over 15 years of experience, the factory has become the OEM provider to some world-famous brands. The continuous efforts on research and development and the concentration on our quality control brought our long-term and reliable orders from all over the world, including Europe, Southeast Asia, East Asia, the Middle East, South Africa, Oceania, South America, etc.

News

-

-

Mechnical PTC Energy Saving Space Heaters excel in heating speed due to their unique working principle and highly efficient heating elements. Here's a detailed explanation of the heating speed of Mech...

READ MORE -

Digital 3D Flame Electric Ceramic Heater With LED Display And Handle shows many significant innovations compared with traditional heaters.This electric ceramic heater uses 3D flame technology to bring...

READ MORE

Message Feedback

Industry knowledge Extension

How does Ice Crusher effectively prevent ice cubes from splashing and scattering during the process of crushing ice cubes?

First of all, we should pay attention to the design of the Ice Crusher crushing chamber. An excellent crushing chamber design can effectively limit the range of movement of ice during the crushing process. An enclosed crushing chamber is a great option as it completely seals the ice inside, reducing the chance of ice splashing. In addition, we can also install appropriate baffles or protective nets inside the crushing chamber. These devices can effectively block the possibility of ice cubes being ejected due to the impact force generated by crushing.

Secondly, optimizing the crushing mechanism is also key to preventing ice from splashing and scattering. Choosing a motor with low speed and high torque can ensure a smoother crushing process and reduce ice splashing caused by high-speed rotation. In addition, the spacing and angle of the crushing knives are adjusted to adapt to ice cubes of different sizes and shapes, ensuring a more uniform and stable crushing process, thereby reducing the scattering of ice cubes caused by uneven stress.

In addition to design considerations, we can further prevent ice from splashing and scattering by adding ice fixtures. Before crushing, special clamps or conveyor belts can be used to firmly fix the ice cubes, so that even during the crushing process, the ice cubes can remain relatively stable and reduce splashing and scattering caused by movement.

In addition, it is also necessary to set up protective covers and baffles. Installing a strong protective cover on the outside of the crusher can effectively prevent ice from splashing outside the operating area and protect the safety of operators. At the same time, a baffle is installed at the exit of the crushing chamber to guide the crushed ice cubes to flow to a predetermined collection area to prevent the ice cubes from being scattered to other places.

For operators, enhanced training and safety awareness are also crucial. Through professional training, operators can become familiar with Ice Crusher's operating methods and safety regulations and master correct operating techniques. At the same time, operators are reminded to maintain a high degree of vigilance during the crushing process, always pay attention to the movement of the ice, and take timely preventive measures to ensure the smooth progress of the entire process.

Finally, we cannot ignore the maintenance and upkeep of Ice Crusher. Regular inspection and maintenance of the crusher to ensure it is in good working condition can effectively reduce ice splashing and scattering caused by mechanical failure. In addition, promptly cleaning up the residual ice and debris in the crushing chamber and keeping the inside of the crushing chamber clean is also one of the important measures to prevent ice from splashing and scattering.

First of all, we should pay attention to the design of the Ice Crusher crushing chamber. An excellent crushing chamber design can effectively limit the range of movement of ice during the crushing process. An enclosed crushing chamber is a great option as it completely seals the ice inside, reducing the chance of ice splashing. In addition, we can also install appropriate baffles or protective nets inside the crushing chamber. These devices can effectively block the possibility of ice cubes being ejected due to the impact force generated by crushing.

Secondly, optimizing the crushing mechanism is also key to preventing ice from splashing and scattering. Choosing a motor with low speed and high torque can ensure a smoother crushing process and reduce ice splashing caused by high-speed rotation. In addition, the spacing and angle of the crushing knives are adjusted to adapt to ice cubes of different sizes and shapes, ensuring a more uniform and stable crushing process, thereby reducing the scattering of ice cubes caused by uneven stress.

In addition to design considerations, we can further prevent ice from splashing and scattering by adding ice fixtures. Before crushing, special clamps or conveyor belts can be used to firmly fix the ice cubes, so that even during the crushing process, the ice cubes can remain relatively stable and reduce splashing and scattering caused by movement.

In addition, it is also necessary to set up protective covers and baffles. Installing a strong protective cover on the outside of the crusher can effectively prevent ice from splashing outside the operating area and protect the safety of operators. At the same time, a baffle is installed at the exit of the crushing chamber to guide the crushed ice cubes to flow to a predetermined collection area to prevent the ice cubes from being scattered to other places.

For operators, enhanced training and safety awareness are also crucial. Through professional training, operators can become familiar with Ice Crusher's operating methods and safety regulations and master correct operating techniques. At the same time, operators are reminded to maintain a high degree of vigilance during the crushing process, always pay attention to the movement of the ice, and take timely preventive measures to ensure the smooth progress of the entire process.

Finally, we cannot ignore the maintenance and upkeep of Ice Crusher. Regular inspection and maintenance of the crusher to ensure it is in good working condition can effectively reduce ice splashing and scattering caused by mechanical failure. In addition, promptly cleaning up the residual ice and debris in the crushing chamber and keeping the inside of the crushing chamber clean is also one of the important measures to prevent ice from splashing and scattering.

English

English Deutsch

Deutsch 中文简体

中文简体